When it comes to heating and lighting our homes, many find their desire to see and keep warm at odds with our best intentions to cut carbon emissions and reduce the rate of climate change. One obvious way to preserve our standard of living and salve our consciences, at least until science can endow us with better sustainable energy sources, is to come up with ways to reduce the impact of fossil fuels, such as systems to capture the CO2 that would normally go up the chimney. The problem hitherto is that materials and chemicals capable of doing this have been either very expensive, hazardous, and hard to make at a meaningful scale, or the cost of using them is prohibitive. But now scientists in the US think they might have hit on a substance that won’t break the bank. Aluminium formate naturally forms a molecular sieve with holes just the right size to grab and loosely hold on selectively to molecules of CO2. It’s cheap, easy to make, and can soak up a lot of the gas before it needs flushing to regenerate it. It’s the brainchild of Hayden Evans and, kicking us off, Craig Brown…

Craig - Some materials, it's very energy intensive to release the CO2 once you've captured it and that's the energy penalty. So we've been working on materials that are naturally selective for CO2 over the other major components of gases in the air, like nitrogen for instance. And so if you selectively capture the CO2, you are reducing that energy penalty. Another concept in the cost of all of this is the capital cost, how much it costs for the system. And so we found a material that's both selective and extremely cheap that could be a candidate for this type of selective capture. Pingxiang Metal Tower Packing

Chris - And Hayden, would the notion be then that you put this between the source of the CO2 and the atmosphere, so it's basically selectively sieving out the CO2 instead of just dumping it into the air? Hayden - Yeah, so that's generally the gist of these kinds of materials, right? Is that you're trying to find something that you can engineer a process where you have a point source burning the fossil fuels, you're generating the CO2 and then along the way before it's released into the atmosphere, the CO2 is quickly sucked up in some meaningful amount into our material. And then what we launch into the atmosphere is just predominantly nitrogen.

Chris - What's the magic chemical?

Hayden - The chemical itself is aluminum formate. The beautiful thing about this material is that it is very simple in its composition. It's made from chemicals that are very non laborious, really to combine and create the material. And then to get it to a state where it can capture carbon is very straightforward because the material is porous, it is ready to capture CO2, when it's exposed to it in the right conditions.

Chris - And is that process reversible? So once it gets saturated, those pores in the material are full of carbon dioxide, can you just heat it up, drive the CO2 off it's back to ready to capture more?

Hayden - Yeah. And the beauty of this material is that you're trying to find a material that grabs the carbon just tightly enough, but not so much so that it's very difficult to release it after the fact. Right? And so our material does this that's able to sort of grab the CO2, load it inside of it, and then if you heat it up ever so gently, it will release or burp the CO2 at our discretion, right when we decided that's a time for it to release.

Chris - And how good is the material, Craig? When you actually look at how much carbon dioxide it can lock away, what's the performance like?

Craig - If you have a kilogram of this material, it'll absorb about 20% of its own mass in CO2.

Chris - Is that good if, if one compares with other materials and chemicals that people have tried to use? Is that good?

Craig - There's more than one factor that you're looking at in this process, but it is good. So you're looking at the selectivity, how easy it is to regenerate, you know, optimizing the heat you have to put in to get the CO2 out, but that 20% value is very good. Yes.

Chris - I'm just thinking though, if one takes a big power station, some of our coal fired stations that we've been busy closing down here in the UK would easily eat through tens of thousands of tons worth of coal on an afternoon. That means presumably then you would need hundreds of thousands of tons of this material to get all the CO2 from one power plant, wouldn't you?

Craig - Chris, I think you've hit the nail on the head there. This is really a big scale up problem. So we have some interesting materials that could potentially capture CO2 selectively in a process here. The problem is getting those tens of thousands of tons and that becomes a resource problem and a cost problem. The great thing about this material is made of cheap commodities like Hayden was saying. So we can easily scale up the process to make this and just on the back of the envelope calculations that we've been doing is, you know, as basic fundamental scientists we're talking about two, $2 per kilogram, something like that. So you can imagine that the scale up is quite possible with these materials. There's also an interesting twist in this. When we capture the CO2, there's a possibility that we can take that CO2 and convert it into one of the building block chemicals that make up the material in the first place. So it's almost like a closed cycle that we can reduce the final cost of the product by using the CO2 as a commodity to make it even more of the material in the first place.

Chris - That was going to be my next question actually to you Hayden, which is, okay, you say you can make tens of thousands of tons of this material to soak up the waste stream from the power plant. What do you do with all the CO2? So is there the potential to, to get it out easily and then put it somewhere into processes like this or, or even into fuels for example? Cause there are now people working actively on turning CO2 back into fuels.

Hayden - Yes. This is sort of almost the keystone sort of problem in this. Okay, great, you've captured all the CO2, you've done it now, Hooray. But obviously you got to do something with the CO2, right? Otherwise you're just sort of going to be generating an infinite amount of CO2. And so there's a lot of research where they're trying to turn CO2 into usable fuels or just commodity chemicals. And so our vision for how aluminum formate or you know, we call it Alf, but how this material is sort of the cornerstone of this CO2 economy is because if you can start to turn CO2 into the compound that we use to make reagents, then you've now got this, you know, recyclable loop where, where you have a viable place to put the CO2 at least to a certain point.

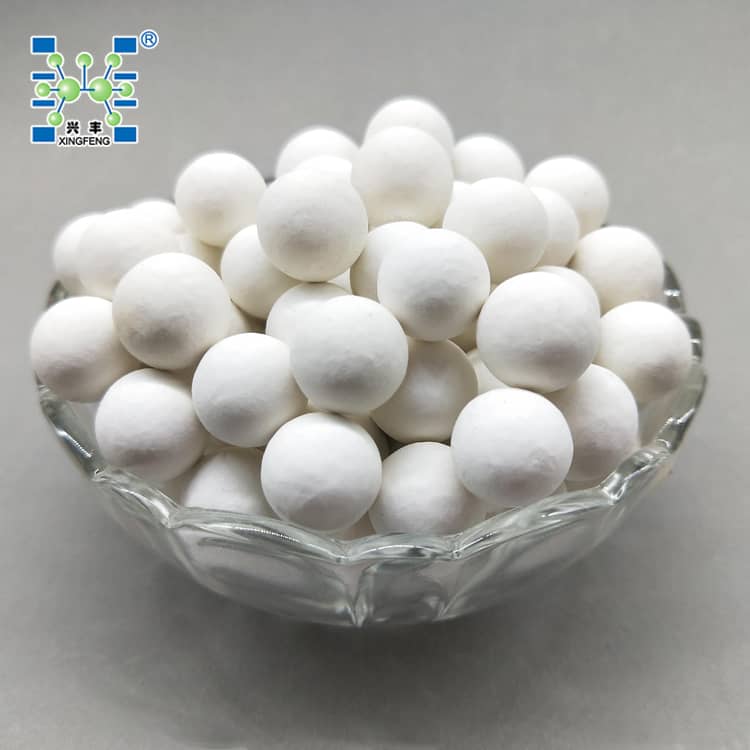

insulating glass molecular sieve ©The Naked Scientists® 2000–2020 | The Naked Scientists® and Naked Science® are registered trademarks created by Dr Chris Smith. Information presented on this website is the opinion of the individual contributors and does not reflect the general views of the administrators, editors, moderators, sponsors, Cambridge University or the public at large.